imes-icore CORiTEC systems are like no other.

Like no other.

imes-icore CORiTEC systems are solutions for all Dental professionals.

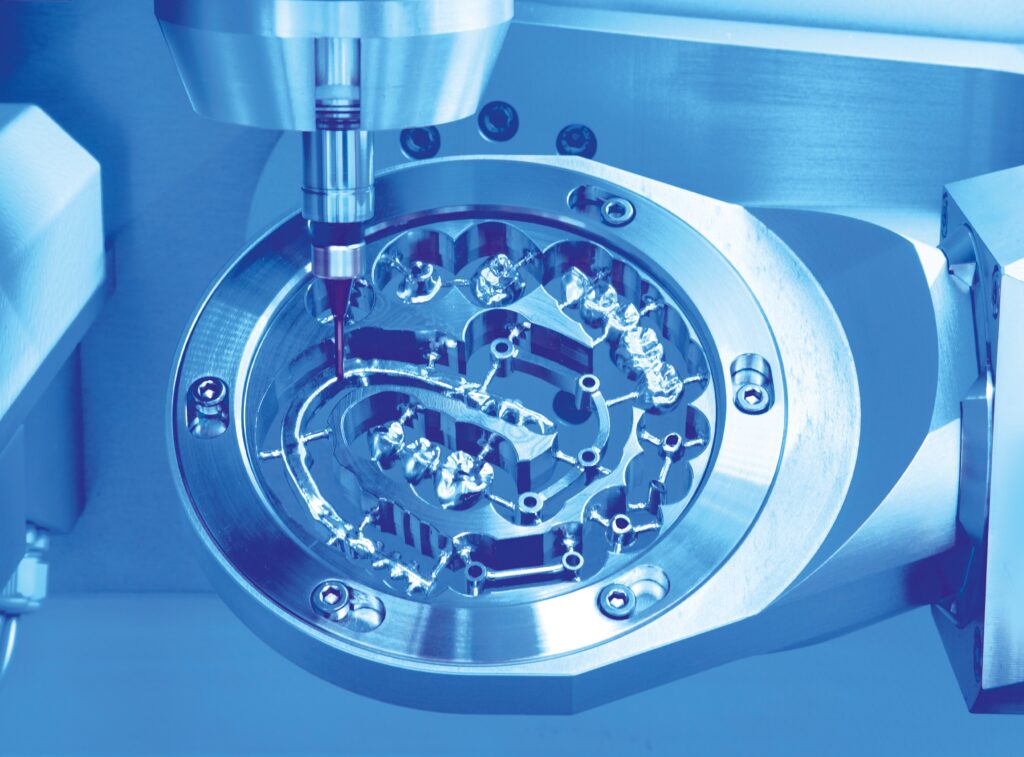

Optimally matched machines and consumables guarantee effective production processes.

imes-icore GmbH are the only company in the world to offer a solution optimally tailored to its customers for virtually every milling center, laboratory and practical size.

In addition to the milling systems, we offer integrated solutions that ensure that you’re operating a reliable workflow from day one.

CORiTEC CHAIRSIDE SERIES

Milling machines for practices that want lab-quality prosthetics.

The CORiTEC one+ is the high-end model in the chairside area. Due to the 5-axis simultaneous technology, the C-Clamp holder and the blank holder can be integrated in addition to the single universal holder.

This generates new application possibilities and more flexibility for creating the expected tooth restoration.

The compact and stable basic design of the machine ensures precise work in block and blank shapes.

CORiTEC LAB -150i/250i SERIES

Truly flexible and powerful machines in smaller spaces.

The highlight in the stable is the NEW 250i PRO+. A compact machine weighing under 100kg that mills titanium bars. You read correctly.

The CORiTEC 250i PRO+ is even ideally suited for the demanding processing of metal blanks (CoCr and Ti). Of course, all other materials can also be professionally wet and dry milled or grinded.

The optimally matched axis drives work almost vibration-free and thus ensure excellent production results. The solid basic structure made of an aluminum mono-block cast body ensures low-vibration movements.

CORiTEC LAB – 350i & 350i X PRO SERIES

Industry leading milling machines for performance and precision. The most popular imes-icore CORiTEC series.

Our best selling machine and the Industry standard, CORiTEC 350i PRO+ is the leading choice for clients wanting to produce All-on-X prosthetic workflows amongst every other conceivable indication. The NEW 350i X PRO is indeed, our neXt level.

A combination of new, perfectly tuned control and drive components ensures the highest performance in this machine segment. Processing times reduced by up to 50% combined with excellent surface quality means significant increases in workload and enhances the price-performance ratio.

The new zero point clamping system generates 4 times XtraPower clamping force. The resulting stiffness and further reduced vibration

characteristics allow a quantum leap in performance. In combination with the extremely powerful 3 kW milling spindle, the highest demands on surface quality are achieved and new standards are set in this machine segment.

CORiTEC MILLING CENTRE

650i SERIES

Future oriented technology for production on an industrial scale.

These are PREMIUM machines for PREMIUM requirements.

Equipped with high-quality industrial CNC technologies, such as granite structure, linear drives in the linear axes, torque motors in the rotary axes, as well as digital absolute length measuring systems, and powerful main spindles.

The machine concept impresses with its precise, vibration-free and dynamic motion sequences in the demanding and complex metal working processes.

The CORiTEC 650i loader includes a fully integrated automatic 16-fold blank changer. This enables you to operate the machine system at full capacity around the clock without supervision, while maintaining consistent high precision.

Thus, the machine system is ideally suited for large labs and milling centers where these high-quality standards and large quantities are at the forefront.