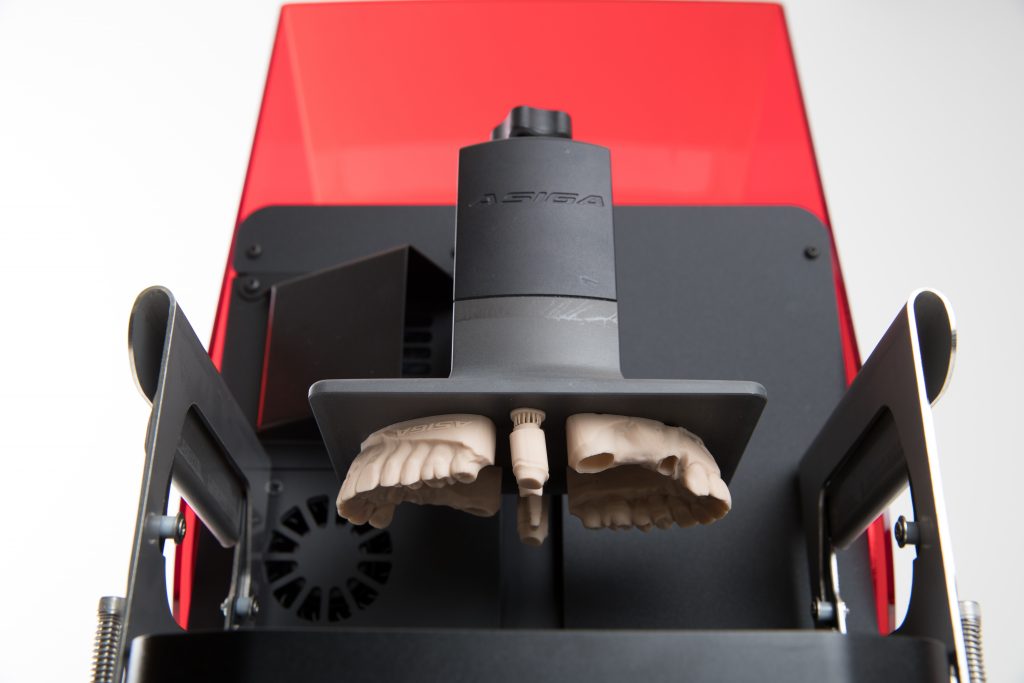

ASIGA MAX 2 UV

Your start in Asiga 3D Printers

The undisputed MAX

Minimum footprint but with maximum productivity.

Globally proven layer formation technologies with every layer is formed under a closely monitored process delivering exceptional consistency as well as performance.

Asiga SPS™ technology

Providing platform positioning feedback ensuring your build platform is where it needs to be for every layer. Thus, Z height precision guaranteed.

Automatic LED power adjustment

Our internal radiometer / light meter provides real-time feedback and automatic cure time adjustment based on actual LED power. Precise layer curing for every layer.

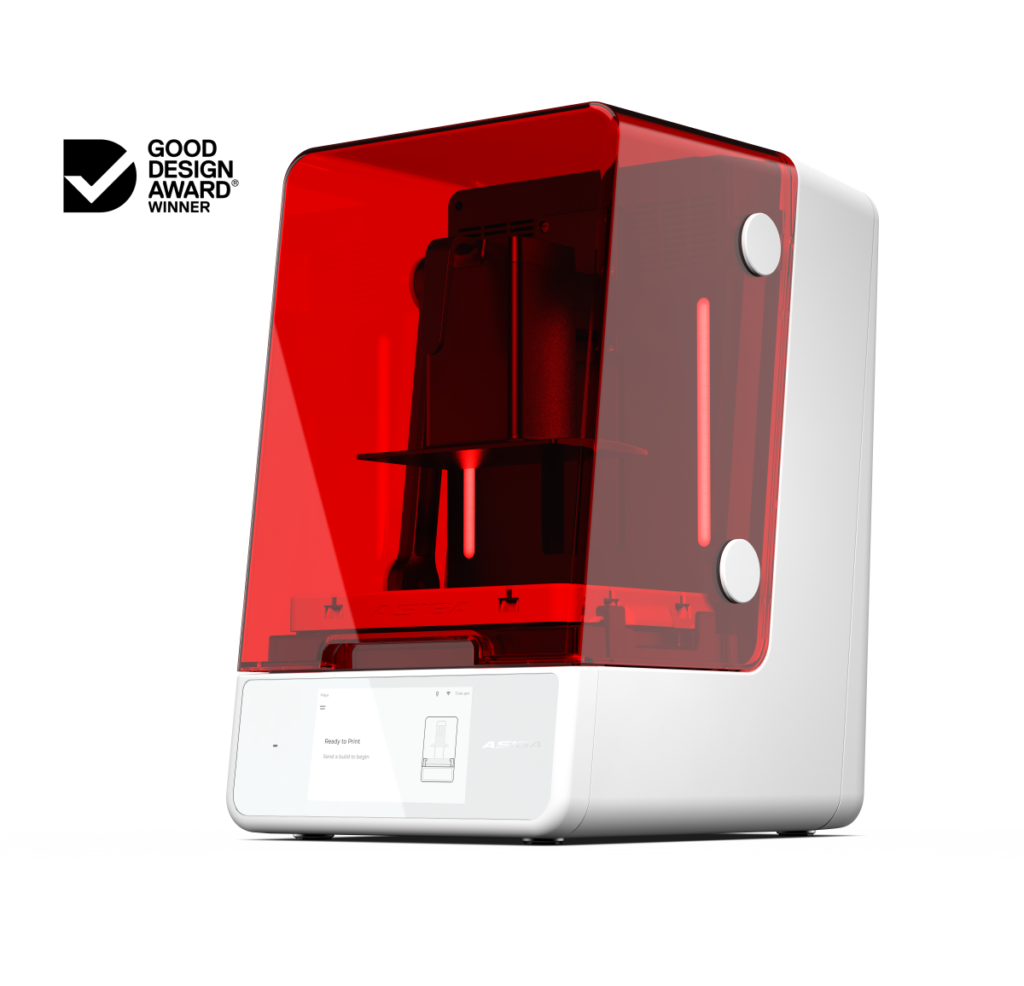

ASIGA ULTRA

Asiga 3D printers’ latest release

4K Imaging Resolution

The latest high resolution imaging chipset delivers extraordinary resolution despite a large build envelope.

Asiga SPS ™ technology

Asiga’s pioneering Smart Positioning System (SPS™) achieves precise layer thickness control of each and every layer, thus ensuring optimal print accuracy and speed.

Infrared Material Heater

Access a new generation of advanced materials with the infrared material heating system. Achieve temperatures up to 70°C.

Magnetic Platform Holder

Streamline your workflow and be automation ready with the new

magnetic build-platform holder. However, no latches, screws or calibration are necessary.

ASIGA PRO4K

Asiga 3D printers’ largest model

The PRO 4K

3D print precision meets volume.

High throughput keeping you ahead of the game.

Crystal Clear 4K Imaging

4K mode for the ultimate surface finish

How does it work?

Asiga 4K mode uses pixel shifting technology to reduce pixel size which enhances surface smoothness and detail definition. This is our default printing mode but you can switch to native mode if required.

No calibration between material changes

Change materials in seconds but without the need for calibration. Our Multi-range feature in Composer you can change materials during a print for a multi-material component.

Unrestricted layer thickness

Specify the optimal layer thickness for the object being printed. We provide default options but with the added bonus for you to specify a value in 1 micron increments. In fact, you can print sections of your build at different layer thicknesses in different materials using Multi-range in Composer.